The control unit offers an easy way to connect a power source for cutting or welding, regardless of the manufacturer, to a Universal Robot UR3, UR5, UR10 (CB series or e-series). Other control tasks would also be conceivable. The control unit uses the emergency stop output signal of the robot and switches 2 remanent relays galvanically isolated. Herewith the emergency stop state can be reported to the external control unit. This enables a safe integration. In addition, two switching signals are galvanically isolated and two analog signals (voltage or current) are provided for connection.

The connections to the external devices are provided by sensor- actuator connectors which allows a quick separation and connection of other technology. The connection to the robot is possible via an optional mounting plate of OH-au2mate also via a connector. As standard, the control box is delivered with open cable end and without mounting plate. The electrical connection to the robot is explained in the instructions included in the scope of delivery and is carried out within a short time.

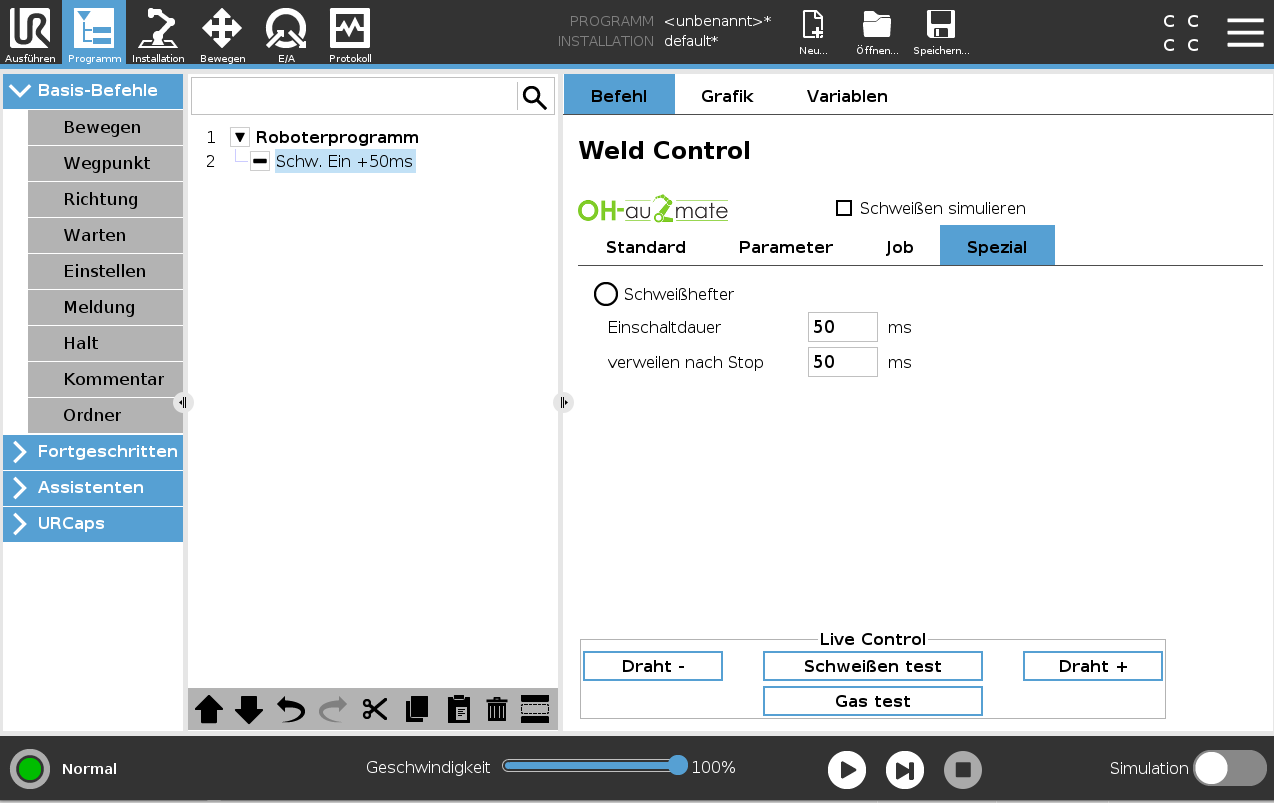

The integration into the software of the Universal Robot is carried out with the help of the URCaps developed in-house. With this cap the outputs can be switched and analog signals can be output in scaled form. Conceivable would be a switching output to start/stop the welding process, analog outputs for the wire feed and adjustment of the current. These functions are already provided and after a short installation complex tasks can be easily integrated into the robot.